Factory Solutions

Factory Solutions

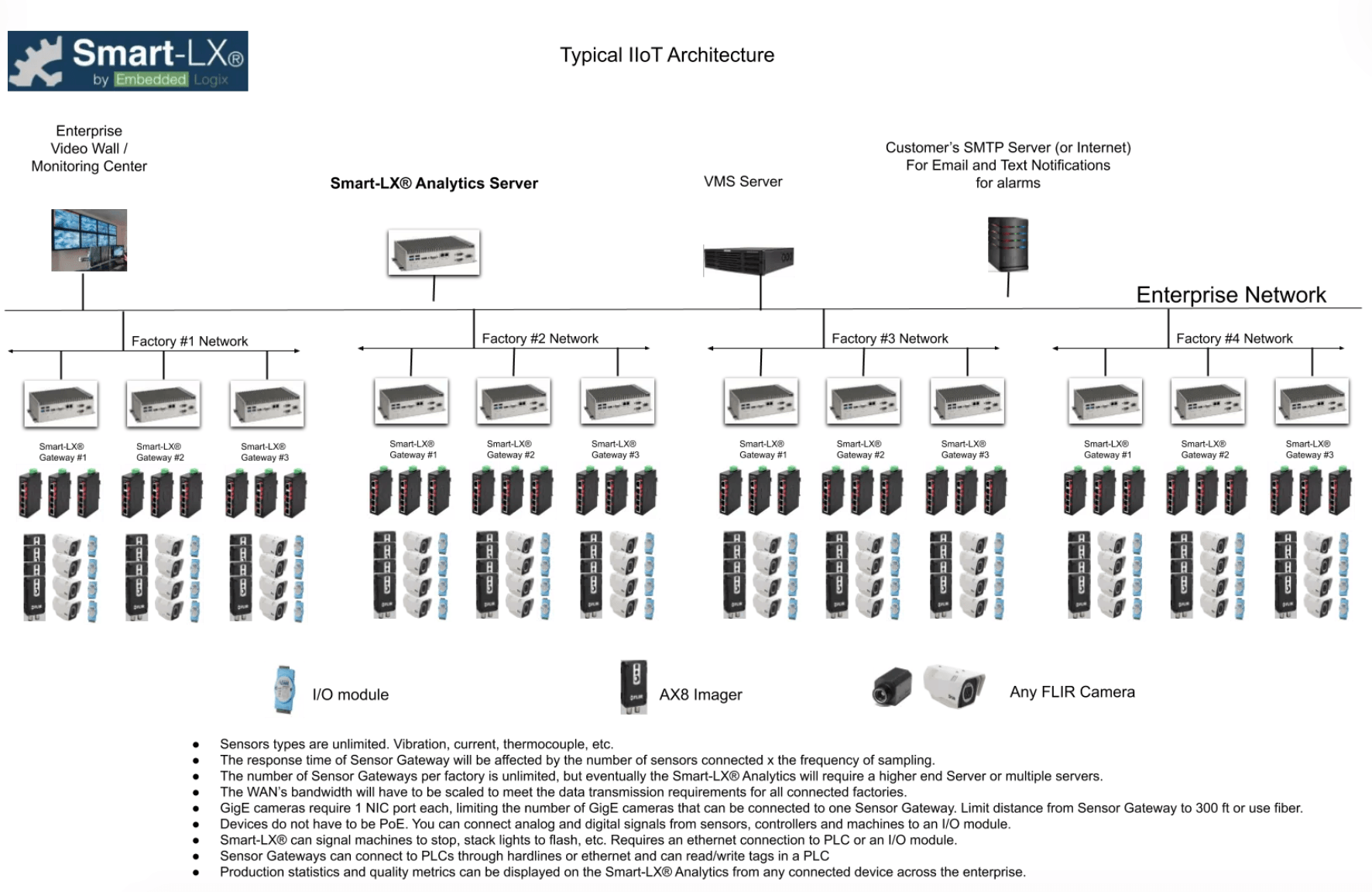

Communicate with legacy devices, new devices, and future devices all from one platform. Feed the Smart-LX® on premise Cloud, or feed a hosted Cloud.

Smart-LX® Sensor Gateway:

Connect any

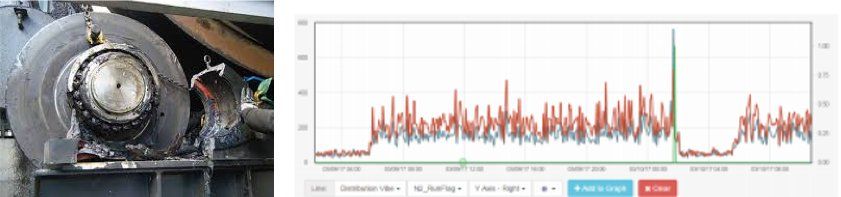

sensors to Smart-LX®, not just infrared and machine vision cameras. Vibration sensors can tell you things about the health of your motors and pumps 24/7. If mounts are starting to loosen, bearing(s) are worn, or an unbalance has developed, you will get an early warning from Smart-LX® before further damage occurs.

Vibration monitoring can prevent disasters like this one

Smart-LX® communicates seamlessly through signal modules to digital signals, analog signals, and specialty sensors to

enable legacy devices to play inside our ecosystem as well as today’s

ethernet and wireless devices.

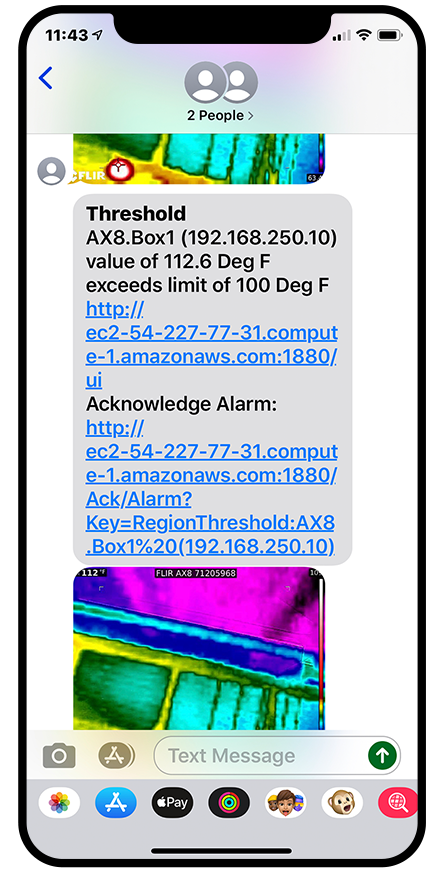

- A text can be sent to a recipient(s) or group(s)

- An email can be sent to a recipient(s) or group(s)

- PLCs can communicate hardline or ethernet to Smart-LX® Sensor Gateways

- Security can receive a VMS alert with an image feed and message if “Assess Fire Risk” Alarm is triggered

- Warnings continue to escalate until a responder has “adopted” the warning

Benefits of Smart-LX®

24/7 Automated Process and Product Monitoring End-to-End Platform

- Consumes data for analysis

- Performs automated analysis on data

- Presents on-demand health status dashboard for hopper levels, tank levels, etc.

- Includes simple and complex rules for customizing alarms

- Offers multiple methods to present alarms to users

- Becomes an expert system with your input over time

New application requirements can appear during the development, deployment, or during the first few months of actual use. It is not unusual for a client to discover that a legacy system should have been integrated, or that a new sensor has just been installed in the environment that would add substantial value to the application.

An agile

application platform is critical to enable the system integrator and client to readily adopt new analytics ideas, sensor data, or ecosystem integrations.

Benefits of Smart-LX®

Factory Solutions

- Save Time & Money

Save time and money through real-time analytics so you can plan maintenance instead of reacting to crisis

- Quick Assessment

Gauges with ”safe” zone to easily and quickly assess situation

- No Need to Monitor 24/7

No dedicated personnel watching a monitor, alarms are sent to any connected device

- Enterprise View

Have an enterprise view of the condition of all assets

- Data Playback

Data playback mode to review what lead up to an event

- Insights to Your Device

Be engaged through insights sent to your connected devices

- Warnings Ahead of Time

Receive warnings of trends developing and other custom analytics tracking

- Equipment Comparison Dashboard

Compare equipment across multiple factories on one dashboard

- Performance Insights

Engage employees with performance insights

- Elevate Customer Satisfaction

Elevate Customer Satisfaction by preventing unplanned downtime

- Meaningful Data

Empower your data scientists and operations personnel with meaningful data, not mountains of data

Receive Early Warnings Before Further Damage Occurs

Text messages can be just an error number or can contain links to videos and show trends developing, even images displayed to help diagnose a problem.

Implementation

Designed with robust factory integration in mind

100% inside your firewall or AWS Cloud hosted if you prefer.

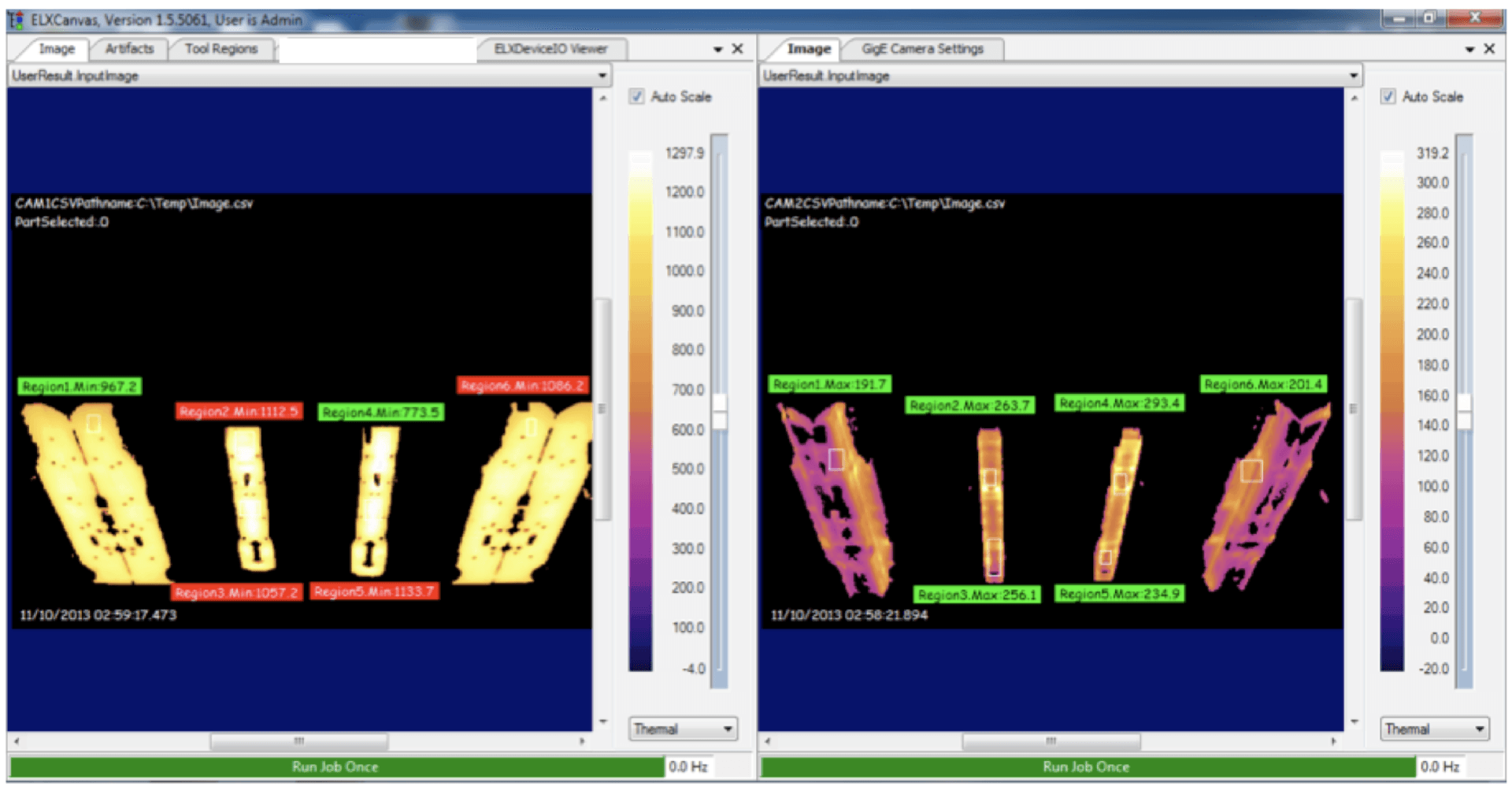

Includes an advanced visualization engine providing end users with near real-time data insights with thermal images and video clips of changes leading up to an event. Smart-LX combines engaging imagery and context rich, real-time data to help maintenance and operations manage their production and process goals.

Near real-time data from assets to smart phones and any connected devices.

Data filters help factories identify which brands of assets are performing better over short and long periods of time. A large selection of filters are available for sorting data into meaningful insights, like assets running similar production rates, brand specific hardware, facility specific performance, and many more.

Historical data facilitates goal setting and demonstrates success over time.

Integration is Easy

Smart-LX® Enterprise Analytics License comes pre-installed on a server (can be installed on a customer provided server).

Sits on customer’s network, 100% inside the firewall or Cloud Hosted option.

User groups are defined, and dashboards are configured for each group.

Notifications are established by groups, individuals or both and can be sent to smart phones, tablets and workstations by text or email.

Smart-LX® Sensor Gateway Licenses come pre-installed on Gateway industrial computers (can be installed on customer provided computers).

Any type of sensors can be added to the Gateway. Ethernet devices, analog, digital, RTDs and many more.

Smart-LX® Sensor Channel Licenses are enabled on the Sensor Gateways as required.

Example of operator screen for infrared sensor monitoring a “hot metal stamp” operation with Smart-LX® Sensor Gateway software.

About Our Team

Over 35 Years

Our company has been in the Test and Measurement business for over 35 years.

Thousands of Installations

We have thousands of Test and Measurement/Analytics installations across North America, South America, Asia, and Europe.

Trained & Certified

We are trained in substation monitoring.

We are Certified Thermographers.

We are a FLIR Technology Partner.

Contact Us to locate an Integrator near you

Or to become an Integrator of Smart-LX®

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Please try again later.